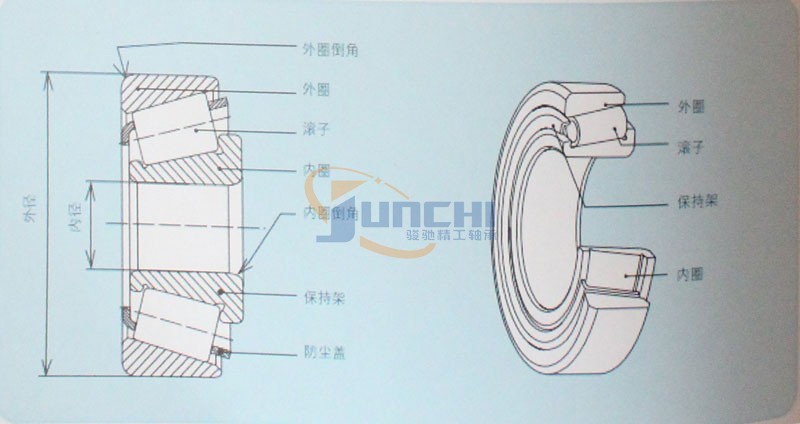

圆锥滚子轴承主要承受以径向为主的径、轴向联合载荷。轴承承载能力取决于外圈的滚道角度,角度越大承载能力越大。该类轴承属分离型轴承,根据轴承中滚动体的列数分为单列、双列和四列圆锥滚子轴承。单列圆锥滚子轴承游隙需用户在安装时调整;双列和四列圆锥滚子轴承游隙已在产品出厂时依据用户要求给定,不须用户调整。

Tapered roller bearings mainly bear radial and axial combined loads. Bearing capacity depends on the raceway angle of the outer race, the greater the angle, the greater the load capacity. The bearings are separable bearings. According to the number of rollers in bearings, they are divided into single row, double row and four row tapered roller bearings. Single row tapered roller bearing clearance needs the user to adjust when installation; double row and four row tapered roller bearing clearance has been given at the end of the product in accordance with the user requirements, without the user adjustment.

圆锥滚子轴承广泛用于汽车、轧机、矿山、冶金、塑料机械等行业。

Tapered roller bearings are widely used in automobile, rolling mills, mines, metallurgy, plastics machinery and other industries.

圆锥滚子轴承使用说明

Description of use of tapered roller bearings

1、圆锥滚子轴承的安装必须在干燥、清洁的坏境条件下进行。安装前应仔细检查轴和外壳的配合表面、凸肩的断面、沟槽和连接表面的加工质量。所有配合连接表面必须仔细清洗并除去毛刺,铸件未加工表面必须除净型砂。

1. The installation of tapered roller bearings must be carried out under dry and clean conditions. Before installation, the matching surface of the shaft and the shell, the section of the shoulder, the groove and the machining quality of the connecting surface should be carefully examined. All mating surfaces must be carefully cleaned and removed burrs. The castings must be clean except for unfinished surfaces.

2、圆锥滚子轴承安装前应先用汽油或煤油清洗干净,干燥后使用,并保证良好润滑,轴承一般采用脂润滑,也可采用油润滑。采用脂润滑时,应选用无杂质、抗氧化、防锈、极压等性能优越的润滑脂。润滑脂填充量为轴承及轴承箱容积的30%-60%,不宜过多。带密封结构的双列圆锥滚子轴承和水泵轴连轴承已填充好润滑脂,用户可直接使用,不可再进行清洗。

2, before the installation of tapered roller bearings should be cleaned first with gasoline or kerosene, dry after use, and to ensure good lubrication, bearings generally use grease lubrication, oil lubrication. When grease is used, grease with excellent properties such as impurities, oxidation resistance, rust prevention and extreme pressure should be selected. The filling amount of grease is 30%-60% of bearing and bearing box volume, not too much. Double row tapered roller bearings with sealed structure and pump shaft bearing have been filled with grease. Users can use it directly and can not clean it again.

3、圆锥滚子轴承安装时,必须在套圈端面的圆周上施加均的压力,将套圈压入,不得用鄉头等工具直接敲击轴承端面,以免损伤轴承。在过盈量较小的情况下,可在常温下用套筒压住轴承套圈端面,用鄉头敲打套筒,通过套筒将套圈均衡地压入。如果大批量安装时,可采用液压机。压入时,应保证外圈端面与外壳台肩端面,内圈端面与轴台肩端面压紧,不允许有间隙。

3. When the tapered roller bearing is installed, the pressure must be applied on the circumference of the end of the ring, and the ring is pressed into it, and the end face of the bearing must not be struck directly with the tools of the township head so as to avoid the damage of the bearing. Under the condition of small interference, the end face of bearing ring can be pressed by sleeve at room temperature, and the sleeve can be knocked by country head, and the sleeve can be pressed into the ring equally through the sleeve. The hydraulic press can be used if the installation is in large quantities. When pressing, it should be ensured that the end face of the outer ring and the end face of the shell shoulder, the inner ring end face and the end face of the shaft shoulder are tightly pressed, and no clearance is allowed.

4、当过盈量较大时,可采用油浴加热或感应器加热轴承方法来 安装,加热温度范围为80℃一 100℃,最高不能超过120℃。同时,应 用螺賴其它适当的方法紧固轴承,以防止轴承冷却后宽度方向收缩而使套圈与轴肩之间产生间隙。

4. When the amount of interference is large, the oil bath heating or the sensor heating bearing can be used to install. The heating temperature range is 80 C 100 C, and the maximum can not exceed 120 degrees C. At the same time, the bearing should be tightened by screw-on or other appropriate methods to prevent the width contraction of the bearing after cooling and the gap between the ring and the shoulder.

5、单列圆锥滚子轴承安装最后应进行游隙的调整。游隙值应根 据不同的使用工况和配合的过盈量大小而具体确定。必要时,应进行试验确定。双列圆锥滚子轴承和水泵轴连轴承在出厂时已调整好游隙,安装时不必再调整。

5, the installation of single row tapered roller bearings should be adjusted at last. The clearance value should be determined according to the different working conditions and the magnitude of interference. When necessary, the test shall be made. Double row tapered roller bearings and water pump shaft bearings have been adjusted clearance when they leave the factory, so they need not be adjusted again.

6、轴承安装后应进行旋转试验,首先用于旋转轴或轴承箱,若无异常,便以动力进行无负荷、低速运转,然后视运转情况逐步提高旋转速度及负荷,并检测噪音、振动及温升,发现异常,应停止运转并检查。运转试验正常后方可交付使用。

6. The rotation test should be carried out after the bearing is installed. First, it is used for rotating shaft or bearing box. If there is no abnormal, it is powered by power without load and low speed operation. Then, the rotation speed and load are gradually increased according to the operation condition, and the noise, vibration and temperature rise are detected and abnormal, and the operation should be stopped and checked. The operation test can be used after the normal operation.