The installation of deep groove ball bearings will affect the accuracy, life and performance of sundry deep groove ball bearings. Therefore, please fully study the installation of deep groove ball bearings, that is, the installation of deep groove ball bearings in accordance with the operating standards including the following items.

―、清洗深沟球轴承及相关零件(Cleaning deep groove ball bearings and related parts)

对已经脂润滑的深沟球轴承及双侧具油封或防尘盖,密封圈深鲰 轴承安装前无需清洗。

There is no need to clean the grease lubricated deep groove ball bearings and two sides with oil seals or dustproof covers.

二、检查相关零件的尺寸及精加工情况(Two. Check the size and finishing of the relevant parts.)

三、安装方法(Three. Installation method)

深沟球轴承的安装应根据深沟球轴承结构,尺寸大小和深沟球轴承部件的配合性质而定,压力应直接加在紧配合得套圈端面上,不得通过滾动体传递压力,深沟球轴承安装一般采用如下方法:

The installation of deep groove ball bearings should be based on the structure of deep groove ball bearings, size and the matching nature of deep groove ball bearing components. The pressure should be directly added to the end face of the tight fitting ring, and the pressure should not be passed through the rolling body. The following method is generally adopted in the installation of deep groove ball bearings.

a.压入配合(A. pressure entry coordination)

深沟球轴承内圈与轴使紧配合,外圈与深沟球轴承座孔是较松时,可用压力机将深沟球轴承先压装在轴上,然后将轴连同深沟球轴承一起装入深沟球轴承座孔内,压装时在深沟球轴承内圏端面上,垫一软金属材料做的装配套管(铜或软钢),装配套管的内径应比轴颈直径大,外径直径应比深沟球轴承内圈挡边略小,以免压在保持架上。深沟球轴承外圈与深沟球轴承座孔紧配合,内圈与轴为较松配合时,可将深沟球轴承先压入深沟球轴承座孔内,这时装配套管的外径应略小于座孔的直径。如果深沟球轴承套圈与轴及座孔都紧配合时,安装时内圈和外圈要同时压入轴和座孔,装配套管的结构应能同时押紧深沟球轴承内圈和外圈的端面。

The inner ring and shaft of the deep groove ball bearing are tightly matched. When the outer and deep groove ball bearing seat holes are loose, the deep groove ball bearing is first pressed on the shaft by the press, then the shaft is loaded with the deep groove ball bearing into the hole of the deep groove ball bearing seat, and the assembly sleeve is made of a soft metal material on the deep groove ball bearing. (copper or soft steel), the inner diameter of the assembly sleeve shall be larger than the Journal diameter, and the outer diameter shall be slightly smaller than the inner ring flange of the deep groove ball bearing to avoid pressure on the cage. Deep groove ball bearing outer ring and deep groove ball bearing seat tight matching, when the inner ring and shaft are loosely matched, the deep groove ball bearing can be pressed into the hole of the deep groove ball bearing seat first, and the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the seat. If the deep groove ball bearing ring is matched tightly with the shaft and the seat hole, the inner ring and the outer ring should be pressed into the shaft and the seat hole at the same time. The structure of the assembly sleeve should simultaneously tighten the end face of the inner ring of the deep groove ball bearing and the outer ring.

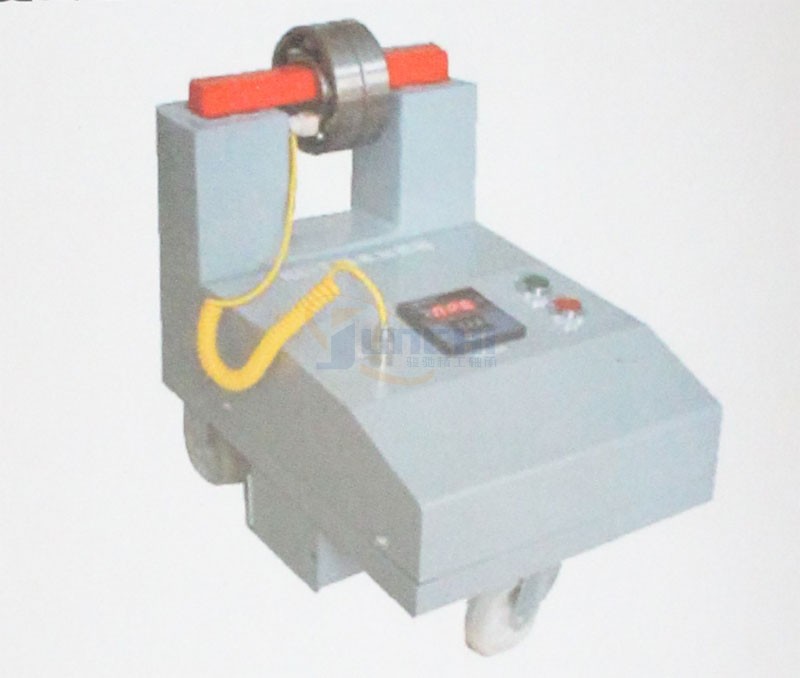

b.加热配合(B. heating coordination)

通过加热深沟球轴承或深沟球轴承座,利用热膨胀将紧配合转变为松配合的安装方法。是一种常用和省力的安装方法。此法适于过盈量较大的深沟球轴承的安装,热装前把深沟球轴承或可分离型深沟球轴承的套圏放入油箱中均匀加热80-100℃,然后从油中取出尽快装到轴上,为防止冷却后内圈端面和轴肩贴合不紧,深沟球轴承冷却后可以再进行轴向紧固。深沟球轴承外圏与轻金属制的深沟球轴承座紧配合时,采用加热深沟球轴承座的热装方法,可以避免配合面受到擦伤。用油箱加热深沟球轴承时,在距箱底一定距离处应有一网栅,或者用钩子吊着深沟球轴承,深沟球轴承不能放到箱底上,以防沉杂质进入深沟球轴承内或不均匀的加热,油箱中必须有温度计,严格控制油温不得超过10CTC,以防止发生回火效应,使套圏的硬度降低。

By heating the deep groove ball bearing or deep groove ball bearing block, the tight fit is transformed into a loose fit installation method by thermal expansion. It is a common and labor-saving installation method. This method is suitable for the installation of deep groove ball bearings with large interference amount. Before hot loading, the deep groove ball bearing or detachable deep groove ball bearings are evenly heated in the tank for 80-100 degrees, and then removed from the oil to the shaft as soon as possible to prevent the inner end of the inner ring and the shaft shoulder close after cooling, and the shaft of the deep groove ball bearing can be reacted again after the cooling of the shaft. Tighten. When the deep groove ball bearing is tightly matched with the deep groove ball bearing seat made of light metal, the heat loading method of the deep groove ball bearing seat can be used to avoid the abrasion of the matching surface. When heating deep groove ball bearings with the tank, there should be a net gate at a distance from the bottom of the box, or the deep groove ball bearing is suspended with a hook. The deep groove ball bearing can not be placed on the bottom of the box to prevent the impurities entering the deep groove ball bearing or uneven heating. The thermometer must have a thermometer in the tank, and the strict control of the oil temperature shall not exceed 10CTC. There is a tempering effect, which reduces the hardness of the sleeve.

C.圆锥孔深沟球轴承的安装( C.Installation of deep groove ball bearing with conical hole)

圆锥孔深沟球轴承可以直接装在有锥度的轴颈上,或装载紧定套和退卸套的锥面上,其配合的松紧程度可用深沟球轴承径向游隙减小量来衡量,因此,安装前应测量深沟球轴承径向游隙,安装过程中应经常测 量游隙以达到所需要的游隙减小量为止,安装时一般采用锁紧螺母安 装,也可采用加热安装的方法。

The conical hole deep groove ball bearing can be directly mounted on the cone with a taper, or on the conical surface of the tight set and the retreating sleeve. The tightness of the match can be measured by the reduction of the radial clearance of the deep groove ball bearing. Therefore, the radial clearance of the deep groove ball bearing should be measured before installation, and the clearance should be measured frequently in the installation process to meet the needs. The clearance should be reduced to a minimum. When installing, the lock nut should be installed normally, and the heating installation method can also be used.

d.推力深沟球轴承的安装( d.Installation of thrust deep groove ball bearing)

推力深沟球轴承的轴圈与轴的配合一般为过渡配合,座圈与深沟球轴承座孔的配合一般为间隙配合,因此这种深沟球轴承较易安装,双向推力深沟球轴承的中轴全应在轴上固定,以防止相对于轴转动。深沟球轴承的安装方法,一般情况下是轴旋转的情况居多,因此内圈和轴的配合为过盈配合,深沟球轴承的外圈与深沟球轴承是的配合为间隙配合。

The coordination of shaft ring and shaft of thrust deep groove ball bearing is generally transition. The coordination of seat ring and deep groove ball bearing seat hole is usually clearance coordination, so this kind of deep groove ball bearing is easy to install, and the middle axis of the ball bearing of double direction thrust deep groove ball bearing should be fixed on the axis to prevent the rotation of the shaft relative to the shaft. The installation method of deep groove ball bearing, in general, is the majority of the axis rotation, so the coordination of the inner ring and the shaft is interference fit, the outer ring of the deep groove ball bearing and the deep groove ball bearing is the coordination of the gap.